7 Simple Techniques For Welding Table

Wiki Article

The Best Strategy To Use For Smaw

Table of ContentsSome Ideas on Mig Welder You Should KnowTop Guidelines Of Arc WelderNot known Incorrect Statements About Welding Shops Near Me Not known Facts About Welding TableThe Only Guide to SmawHow Arc Welder can Save You Time, Stress, and Money.Some Known Facts About Arc Welder.

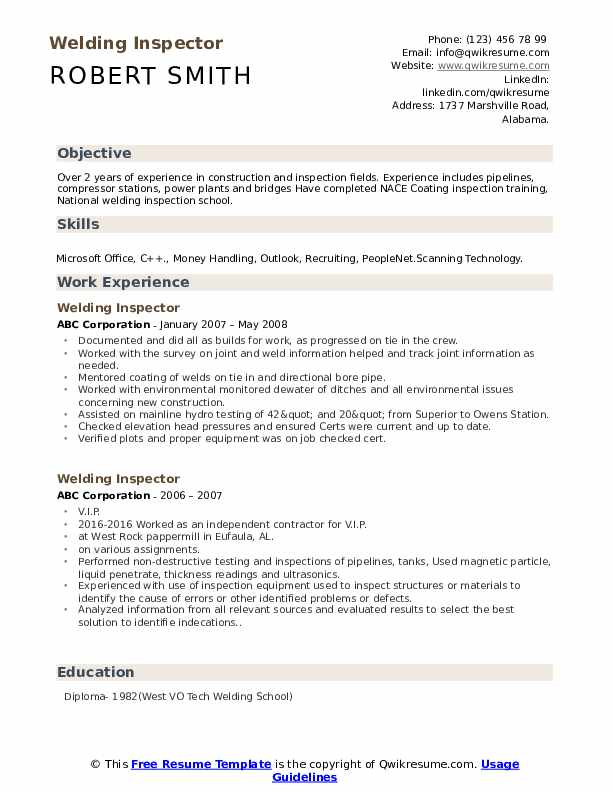

Inspectors determine welded items to make certain that they satisfy specs for dimension. The accredited weld inspector uses tension devices to put stress on weld joints.Welding inspectors videotape the results of tests and also welding examinations. A college education and learning is not required for the majority of welding or welding examination settings, but an associate degree in welding technology can boost the possibilities of landing a job.

Automation does not decrease the need for assessment.

Something went incorrect. Wait a minute and also attempt again Try once more.

Mig Welder for Beginners

Elderly Staff Designer, National Board This write-up was originally released in the Loss 2009 National Board Publication as the initial of a two-part series. Keep in mind: The function of this short article is to provide assessors with a basic knowledge of weld evaluation.While not essential, the inspector needs to discover to read usual weld signs such as the AWS symbols. At the very the very least, the examiner must constantly lug a reference guide to analyze weld symbols. Having actually reviewed all this info beforehand, the assessor will be prepared to identify any troubles as they establish rather than after-the-fact.

The maker or fixing company (certificate holder) has shown at work attracting that a weld joint is to be prepared with a 60-degree bevel and also origin space of 1/16 inch. Unless the bevels are crushed on precision equipment, it is doubtful they will certainly attain a precise 60-degree bevel as indicated.

The nozzle axis is 90 to the level head, and the add-on weld consists of a 3/8-inch fillet weld. The inspector can quickly gauge the fillet weld to ensure compliance.

Welding Table Can Be Fun For Everyone

This example ends up being much more important if the nozzle is set up at an angle aside from 90 (Fig. 3). Using the same nozzle attachment example as described above, allow's check out the weld joint preparation. The certificate owner has defined a 45-degree bevel around the area of the opening in the flat head and the vessel shell.4). The curved shell will certainly offer even more of an obstacle. The assessor will need to establish if the certification holder is referencing the bevel from the vertical axis of the nozzle (Fig. 5) or from the variable recommendation plane of the bent shell (Fig. 6). When bevels are prepared with a reducing torch and also completed with a mill, it is extremely difficult to keep an exact angle.

Inspectors are trained to believe just what their eyes tell them; however when the examiner can not see the internal surface of the tube, it ends up being difficult to accept that scenario. If the tube ends are correctly prepared (beveled) and also a certified welder is using a certified welding treatment, the odds are really good that the welds will be complete penetration.

One "red flag" to a prospective trouble would be if the examiner observes that television ends have not been beveled. The examiner must instantly ask the certificate owner concerning this situation. Maybe as straightforward as the certificate owner having just not carried out that step in the process yet, or maybe as negative as his or her having tried to conserve money and time by not beveling the ends.

Some Ideas on Smaw You Should Know

The welder would certainly require to begin with a huge root space and after that be really mindful not to "press with" excess filler metal to cause weld accumulation on the within of Get the facts the tube.1, stipulation 6. 1, needs welding examiners of all levels to pass an eye exam, with or without rehabilitative lenses, to verify near vision acuity, learn this here now in at least one eye, on Jaeger J2 letters or smaller sized at a range not less than 12 inches. A shade assumption test and a comparison distinction tones of grey examination need to be taken, however the employer develops the acceptance for these 2 examinations based upon the weld examination being executed.

I bear in mind working for a supervisor who was about as arrogant and egotistic as they come. He treated nearly every person he met disdain. He would certainly simply been promoted to foreman and also was attempting to be a goon. We were servicing a pretty high high-rise, his initial "big work." That's where "Mr.

He informed portable welder the inspector he needed to rush up and also leave our method similarly a drill sergeant would inform a new recruit to get down and also do pushups! The assessor really did not say a word; he simply responded as well as walked off. The next morning when we reached the task there was a sea of red around the flooring we were servicing.

It had not been that the welds misbehaved; they simply were "technically" not up to specs. Our welding examiner was not a pleased camper. Our ruffian boss was virtually in rips! Thankfully for us, we were able to talk with the inspector and also discuss what a pinhead our boss was and also that he was not representing our crew.

Rumored Buzz on Cold Welding

Effect test. Etching. Destructive are generally made use of in academic screening, store testing, and also tests welders require to get licensed or employed on at a jobsite.The responsibilities are divided right into 3 main stages; Validate that the material remains in accordance with attracting/ WPS identified as well as traced to an examination certification in appropriate problem (devoid of damages and contamination) WPS is accepted and also offered to welders (as well as assessors). Welding equipment remains in suitable problem as well as adjusted as appropriate.

Identification of welders qualification for each WPS to be made use of and all welder qualification certifications are valid. Welding consumables to be made use of are-as defined by the WPS-stored/controlled as specified by the QC treatment. Joint fit-ups remain in accordance with WPS/ drawings Tack welds are appropriate per criteria, code or WPS.

Make sure climate conditions are appropriate/ abide with Code (problems will certainly not impact welding) when on-site/ area welding. Welding process need to be in accordance with WPS.

The 10-Minute Rule for Smaw

Make certain all reports/records are finished and collated as required. Reference: Inspector Responsibilities By Neal Chapman CSWIP 3. spot welder. 1 Training course note.Report this wiki page